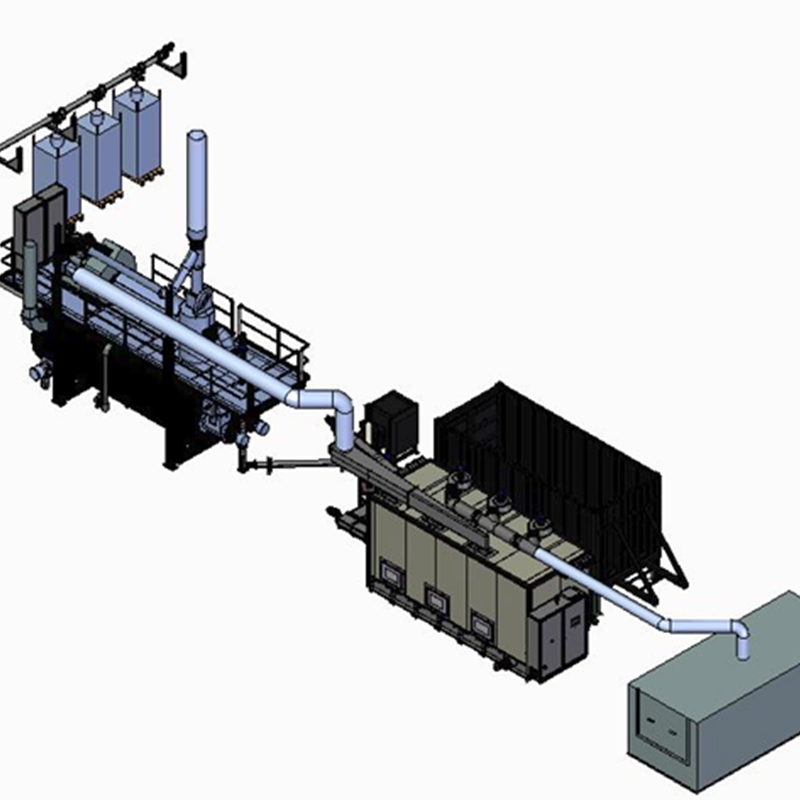

A standard PyroDry solution consists of the following:

- 1 × Walking floor container

- 1 × Speed/rotary drying oven

- 1 × Pelletting machine, incl. 1 × 0.5 cu. m intermediate tank

- 1 × Biofilter system

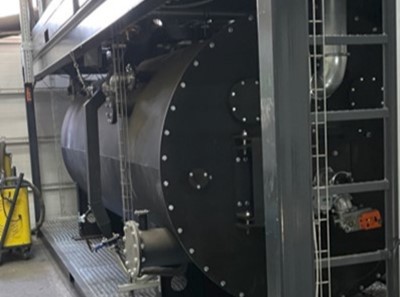

- 1 × Cracker pyrolysis oven

- 1 × Big bag station

- Consolidated facility control system

- All connecting ducts, augers, pipes, etc.

- Complete installation, commissioning, and operator training

- The entire installation is CE-marked.

- Service agreement opportunities

* The above differs only in sizing depending on whether the 3000 or 5000 model is chosen.

* All units are produced in Europe according to EU standards.

PyroDry 3000 & 5000

Regardless of whether the 3000 or 5000 model is chosen, the setup, functionality, and process are the same for all PyroDry solutions and installations.

These facilities convert large volumes of dewatered organic sludge into valuable biochar while reducing CO2 emissions and quantities of harmful substances, including PFAS.

We call it "all-in-one PyroDry solutions”: waste to value - reduce your CO2 footprint - crack dangerous substances - sludge reduction from 10 to 1.

Our model offerings are designed so as to facilitate handling dewatered sludge from the vast majority of treatment plants in Denmark and Norway, as well as biosluge from biogas facilities.

Model offerings:

- PyroDry 3000: can convert approx. 2500 metric tons of dewatered sludge (per year) to approx. 340 metric tons of biochar (carbonizate).

- PyroDry 5000: can convert approx. 5000 metric tons of dewatered sludge (per year) to approx. 675 metric tons of biochar (carbonizate).

The above data is based on dewatered sludge with a dry substance percentage of 20. Dry substance percentages above 20 allow for greater processing volumes.

PyroDry facilities have a modular construction, making it possible to install them in series and create custom solutions capable of handling very high volumes of dewatered sludge.

The installation of automated PyroDry facilities emphasizes a healthy working environment.

PyroDry system and process

A valid, fully automated system and process that converts organic sludge into biochar.

Dewatered sludge is transferred into a container with a walking floor. From there, an auger pulls the sludge into a chambered drying oven which dries and pulverizes the sludge in fractional batches.

The steam from the sludge is cleaned by the drying oven's filter before being directed to the system's biofilter and finally released.

The pulverized sludge is pelletted before being dosed into a pressureless pyrolysis oven, where the pellets become biochar. The oven utilizes the energy and heating value in the biochar, and the extracted pyrolysis gas is returned to the drying oven to heat it and continue the drying process.

Once in operation, the thermal process is self-sustaining and energy-neutral. The system consumes electricity exclusively for material management. The biochar can be filled into big bags with the corresponding system we provide or stored directly in a container.

Operation requires power only for material management, including motors, pelletting machines, augers, and the control system—on the order of 35 kWh, given an input of approx. 500 kg dewatered sludge (20% DS) per hour. The patented PyroDry solution's low energy consumption puts it in a league of its own.

Are you interested in or do you have questions regarding PyroDry 3000 & 5000?

Contact us

Contact us