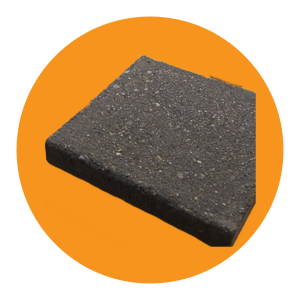

Reduce dewatered sludge by up to 90%, and transform it into a sustainable, valuable product: BioChar

PyroDry's groundbreaking, patented pyrolysis solution tackles challenges that the wastewater sector faces in disposing of dewatered sludge (including biosludge) and converting, neutralizing, or eliminating microplastics, pharmaceutical residues, pesticides, and PFAS with a strong, CO2-reducing pyrolysis technology and an energy-optimized process.

PyroDry: system and process

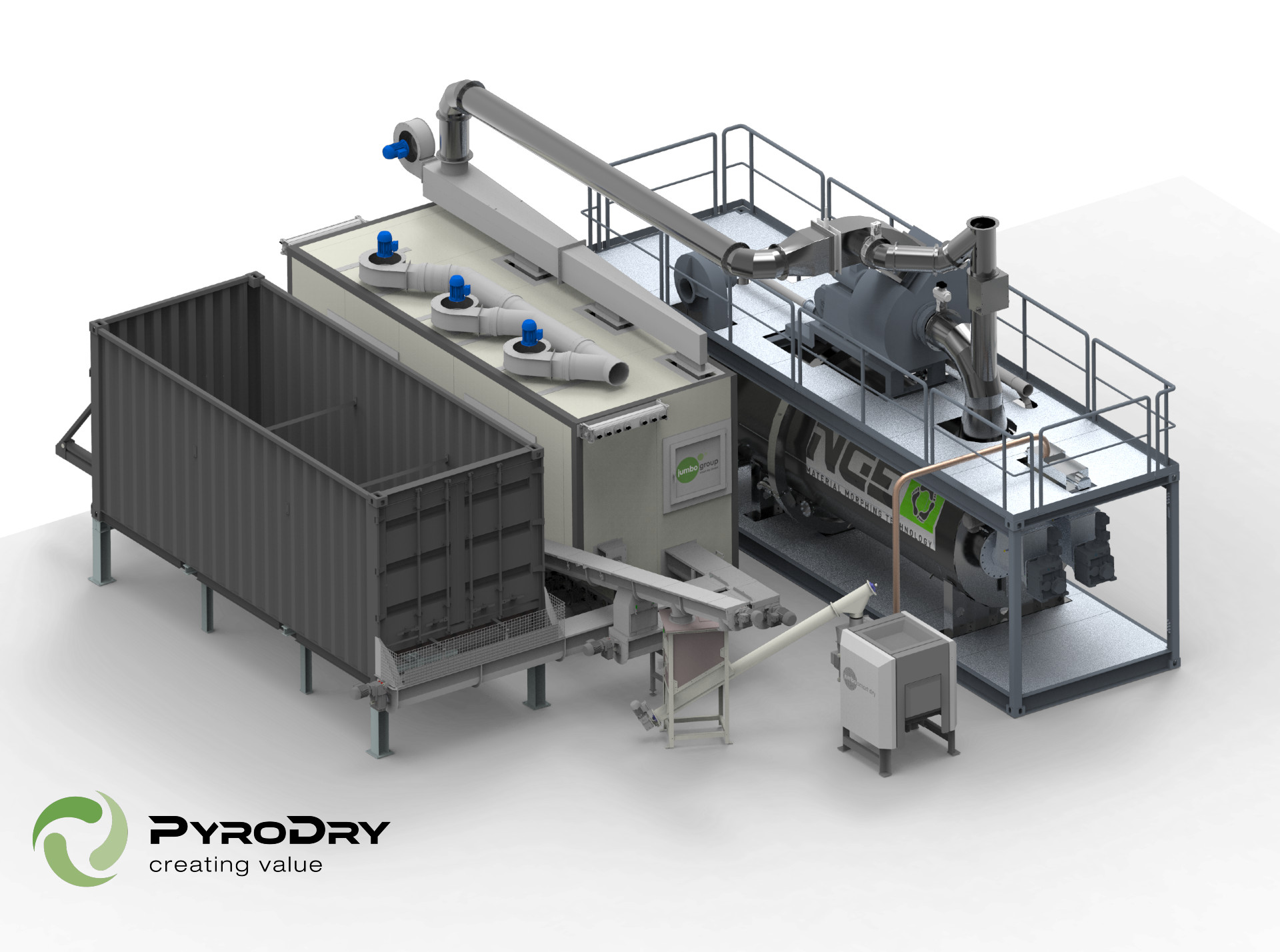

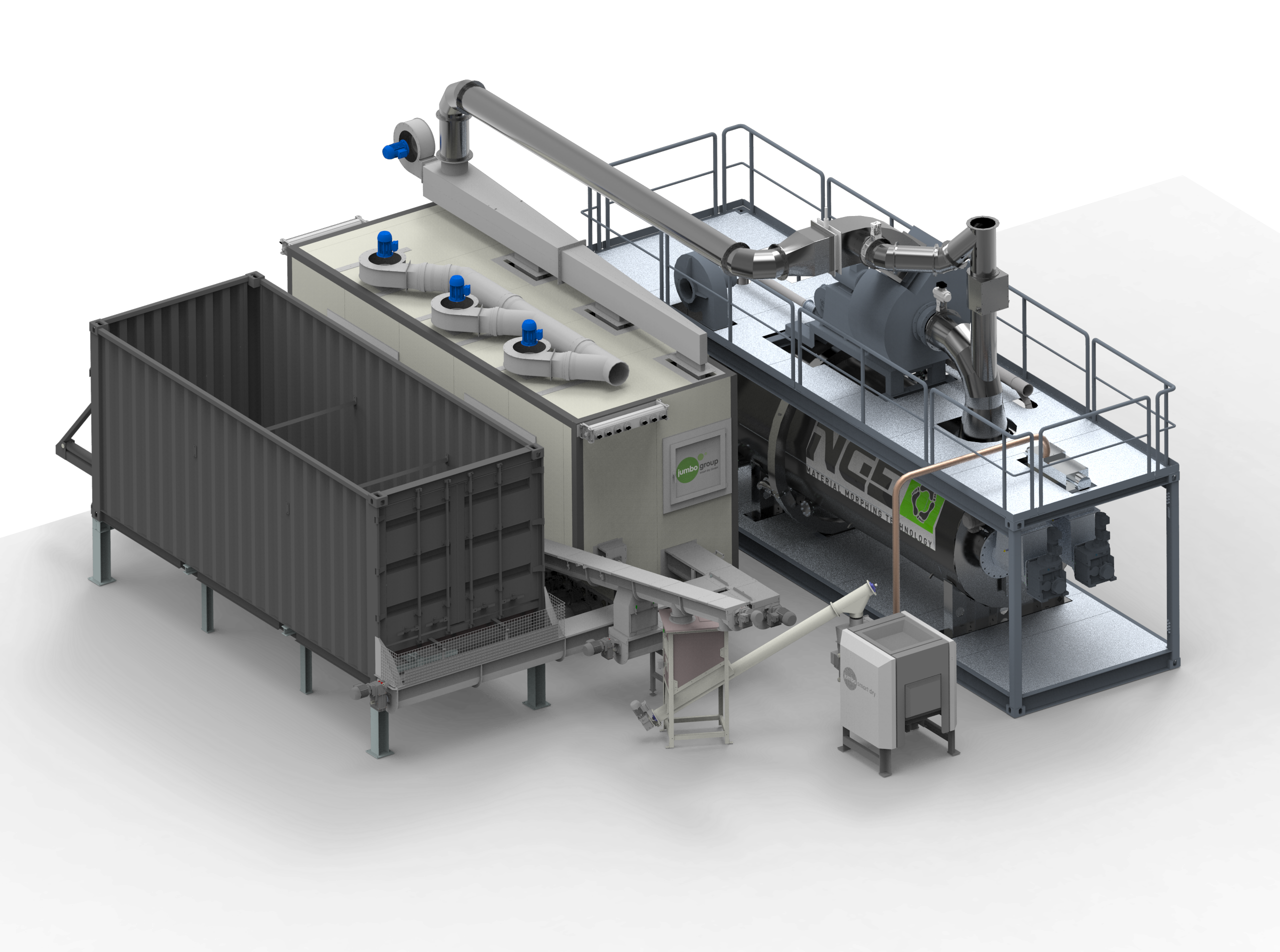

PyroDry is a fully automated, full-scale facility process that converts organic sludge into valuable BioChar using a specially designed and patented drying and pyrolysis oven.

The sludge is dried and pulverized in the drying oven before being formed into pellets and converted into BioChar in the pyrolysis oven. The use of pellets creates a uniform, easily handled substance that is easy to transport and dose into a pressureless pyrolysis oven. The BioChar is subsequently easy to cool.. The result is maximum operational safety, an optimized pyrolysis process, and a product that is much easier to handle, store, transport, and use.

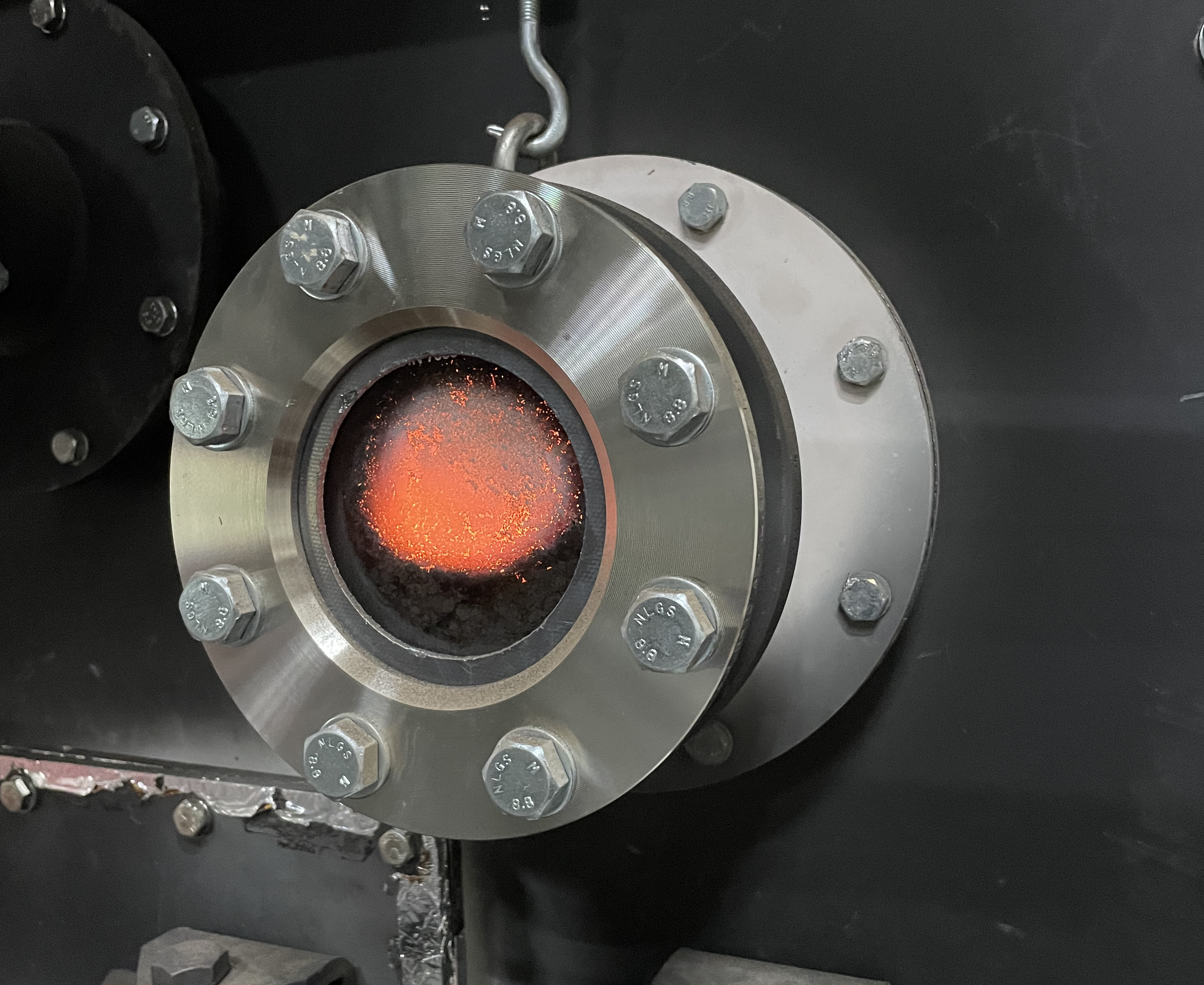

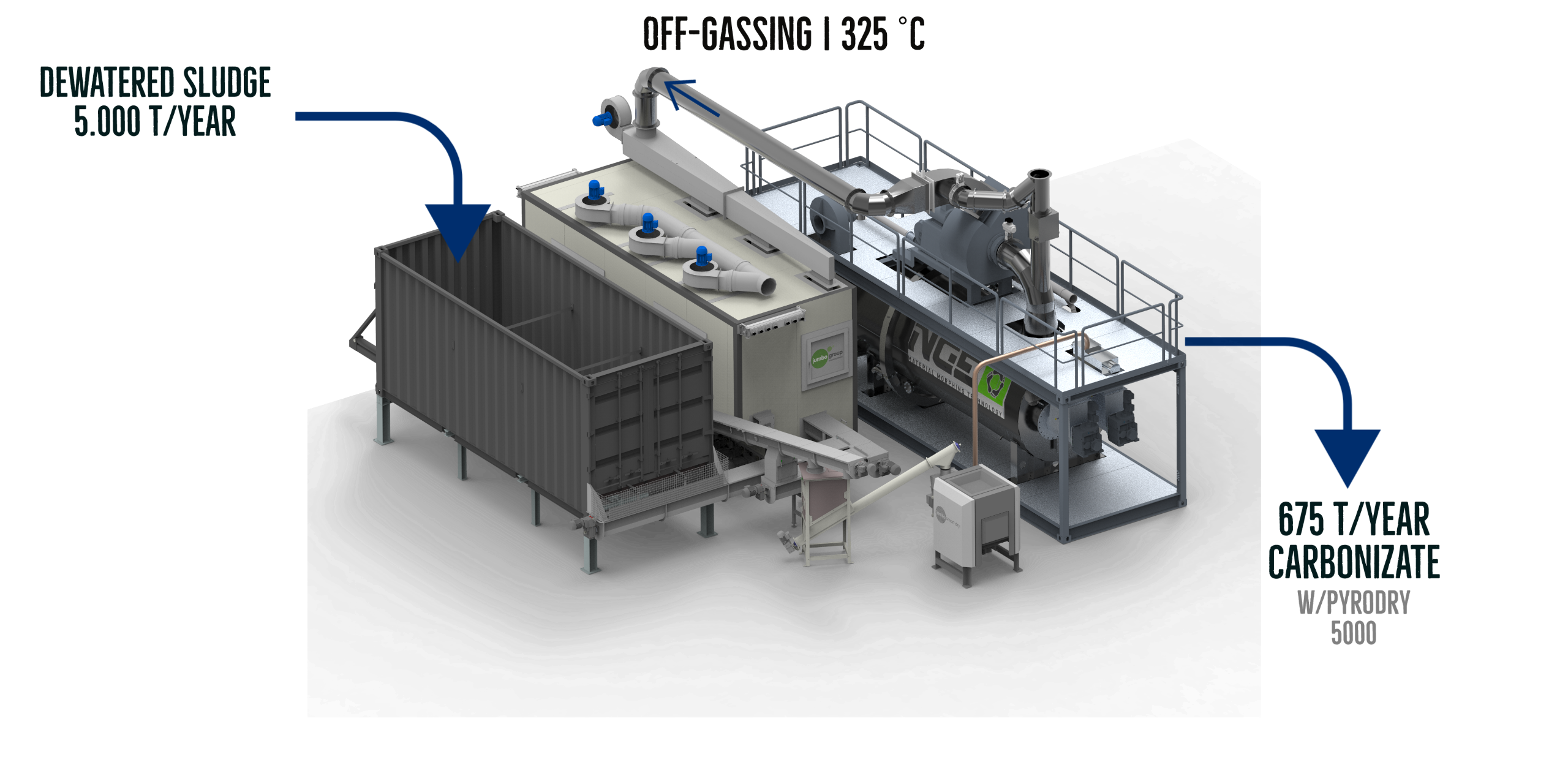

The unique PyroDry system optimally utilizes the energy and heating value of the BioChar. The hot gas (approx. 950°C) generated in the pyrolysis oven is directed into the drying oven. As it makes its way there, it cools (to approx. 325°C) via a fresh air intake. This patented process is responsible for the system's remarkably low energy consumption. Any excess thermal energy can be used for such tasks as heating water or air. As a result, a complete PyroDry facility and system requires about 35 kWh of external energy, given an input of about 500 kilograms of dewatered sludge (DS 20%) per hour.

A PyroDry facility and system consists of numerous unique components and assemblies, including one or more walking floor containers for storing dewatered sludge, a drying oven, a pelletting machine, a pyrolysis oven, a biofilter, and one or more big bag filling stations.

In addition, there is an internally connected system of augers, pipes, etc. and a facility control system. Depending on the model chosen and environmental factors, a complete installation requires about 250 sq. m of frost-free indoor space. This assumes that the biofilter and big bag filling station(s) are installed in suitable outdoor locations, preferably with big bag filling station(s) in a covered area.

Pyrolysis

Pyrolysis is expected to become an increasingly prominent technology and factor in the sustainable and efficient management and disposal of sludge, and it makes the idea behind the waste-to-value principle achievable.

A PyroDry facility and system can reduce dewatered sludge by up to 90%

Pyrolysis is a process in which organic materials is heated in a pyrolysis oven to high temperatures, from about 450°C to about 950°C in a low-oxygen atmosphere, leading to thermal breakdown of the heated material. During pyrolysis, volatile organic compounds are released as gases and solid residues that contain carbon (BioChar) are formed.

PFAS, pharmaceutical residues, microplastics, pesticides, heavy metals, and emissions

When pyrolyzing sludge, it is possible to transform and break down PFAS and PFOS compounds. In independent analyses conducted in collaboration with a utility company, PFAS 22 and 4 can no longer be measured/detected, even though they were demonstrably present before pyrolysis.

The organic material in the sludge, including microplastics, pesticides, and pharmaceutical residues, is converted into gas during pyrolysis. This gas is directed back into the drying oven to be used as a drying medium. It has been oxidized to SO2 in the pyrolysis oven from the released hydrogen sulfide. In the drying oven, a reaction occurs between SO2 and NH3, resulting in the formation of ammonium sulfate. This is returned via the dried sludge to the pyrolysis oven and incorporated into the BioChar.

The majority of the sludge's water evaporates and is discharged as purified water-laden air, first through the filters of the drying oven and then through the system's biofilters. Measurements we have had conducted show dust, ammonia, and odor well below the applicable limit values.

The heavy metals in the sludge are still present in the BioChar after pyrolysis. Some metals break down, but the residual amounts are bound in the BioChar. Measurements of heavy metals in the BioChar show values significantly below the allowed limits for NPK fertilizers.

CO2 and BioChar (with phosphorus, "P"): a valuable and sustainable product

CO2 emissions are reduced by pyrolysis because BioChar, the primary product, itself contains carbon, allowing it to fix CO2 for extended periods of time.

When BioChar is used as fertilizer, it can help to increase carbon fixation in the soil for decades or even centuries to come.

This is because BioChar is a stable, carbonaceous material that does not readily decompose.

A PyroDry facility can reduce and fix 700–900 kilograms of CO2 per 1000 kilograms of BioChar output.

Phosphorus (P) is typically present in organic materials. During pyrolysis, a portion of the phosphorus in these materials can be converted to a more stable form that resists decomposition, slowly releasing phosphorus where BioChar is used as fertilizer.

A slow rate of phosphorus release significantly reduces the risk of phosphorus contamination in aquatic environments.

Thus, pyrolysis can be part of a broader strategy for reducing CO2 emissions, eliminating PFAS and other harmful substances, and improving soil quality using BioChar.

BioChar typically contains 7-12% phosphorus (P2O5).

However, it is important to note that the phosphorus content of BioChar can vary depending on the raw material (sludge) used to produce it and on pyrolysis conditions. BioChar should not be used alone as fertilizer, but as one component of a balanced, sustainable fertilization plan.

Potential applications of Biochar

Fertilizer

Reduces NPK in forestry, agriculture, and gardening, among other applications

Soil improvement

Binds water, enhances pH, absorbs toxins

Odor absorption

For example, at wastewater treatment plants

Productivity enhancement

For example, in biogas production

Raw material

Extraction of phosphorus

Reduction of CO2 emissions

By incorporation in, for example, concrete and asphalt

Fuel

For personal use in a pyrolysis stove

Filter media

For micro-pollutant removal in wastewater

CO2-certificates

The PyroDry system is registered with CDR.fyi, an international organization that certifies CO2reduction processes and businesses, making it possible to purchase CO2 certificates.

Collaboration between Aquagain, PyroDry, and the customer

Aquagain has contracted with PyroDry to provide sales, installation, and after-sale service for complete PyroDry pyrolysis facilities and systems in Denmark and Norway.

The two companies collaborate closely not only to drive further innovation in this area, but also to provide customer-focused consulting services and feedback, taking each customer's specific needs and opportunities into account regarding one or more PyroDry facilities and developing a proposed solution, a business case, and a specific offer.

This collaboration means that both Aquagain and PyroDry are at the customer's side the whole way through, including after system delivery and installation, as well as when service is required.

Where PyroDry facilities can be used

A PyroDry facility can be used with all types of organic sludge, including digested sludge, non-digested sludge, and biosludge. The only requirement is dewatering to at least 20% DS.

System sizes

We primarily offer two PyroDry models:

- The PyroDry 3000 can handle approx. 2500 metric tons of dewatered sludge* (20% DS) per year* equivalent to approx. 340 metric tons of BioChar (carbonizate)

- The PyroDry 5000 can handle approx. 5000 metric tons of dewatered sludge* (20% DS) per year.

* equivalent to approx. 675 metric tons of BioChar (carbonizate)

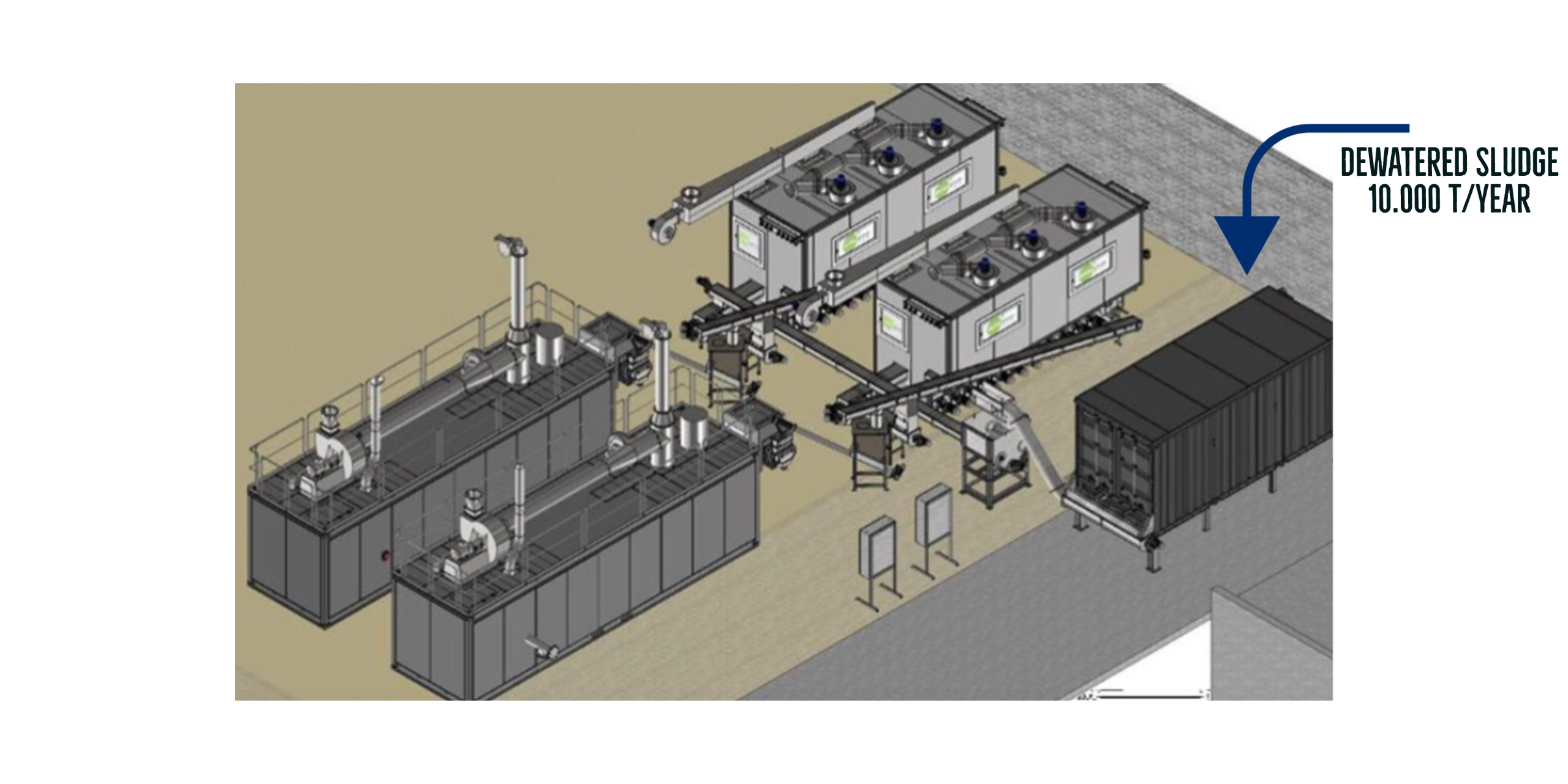

For greater needs, multiple PyroDry lines can be installed.

See a PyroDry plant in action

In Nordhausen, Thuringia, stands this impressive PyroDry 1500 plant. We use the same setup, function, and process, whether it's the 1500, 3000, or 5000 model type. The PyroDry plants are modular, series-installed, and customer-specific, capable of handling very, very large amounts of dewatered sludge.

More than just a machine, PyroDry is a sustainable solution

Today, companies, societies, and the world at large are focused on reducing CO2 emissions, eliminating harmful substances, optimizing energy consumption, and reusing resources (waste-to-value). These are important parameters for making significant improvements to the global environment in all regards.

PyroDry's solution is an investment today for a sustainable tomorrow where circular economics have a role to play.

A PyroDry solution delivers on these key parameters in targeted, specific ways, greatly reducing sludge volumes and CO2 emissions while also minimizing quantities of harmful substances like microplastics, pharmaceutical residues, endocrine disruptors, pesticides, and (last but not least) PFAS.

PyroDry facilities are specially developed with a focus on energy consumption and optimization, emphasizing reuse and utilization of energy already in the system. This is why operating costs are so low. PyroDry's pyrolysis solution turns wastewater sludge and/or biosludge into BioChar, a valuable product with benefits that include the availability of phosphorus as a fertilizer.

The PyroDry solution is the green, sustainable solution of the future for managing wastewater sludge and biosludge.

Value creation and benefits

CO2

- The CO2 is captured in the BioChar

- No CO2 emissions in disposal

- Minimal CO2 emissions (over many years) to deliver BioChar to agricultural and forestry areas

Environment

- Significant reduction of PFAS, microplastics, pharmaceutical residues, endocrine disruptors, and pesticides

- No significant environmentally harmful emissions

- No residues or waste products to be disposed of in landfills

- From Waste to Value

- Part of a sustainable fertilization plan

- Significantly lower CO2 emissions

Energy

- Patented, energy-optimized system with the cheapest energy consumption on the market—nearly energy-neutral

- Any excess heat produced can be repurposed

Finances

- Reduces dewatered sludge by up to 90%

- Sale of BioChar

- Sale of CO2 certificates

- No fees associated with disposal and landfill usage

- No transportation costs for disposal

- Significantly reduced end product handling and storage costs

- Automated system and process do not require additional staff

Branding

- A greener business with a significantly better carbon footprint

- From Waste to Value: sustainable, circular economics

- Achieve a greener, more positive reputation among stakeholders, influencers, society, and the world at large

- Be among the first movers for this innovative idea and sustainable concept—while gaining a strategic edge and benefits in the future

Collaboration

- A valuable collaboration between Aquagain, PyroDry, and the customer from A to Z

- Aquagain has more than 50 years of experience with installations at water treatment plants and similar facilities

- One vendor and one completely installed, full-scale system, including delivery and after-sale service

PyroDry models

We have two PyroDry models: PyroDry 3000 and PyroDry 5000

Want to know more about PyroDry

- Call us and we will be happy to help