Surface treatment

Surface treatment and finishing are often specified out of habit rather than on the basis of closer consideration. When stainless steel is treated, the protective surface is eroded. Oxidation may therefore occur, especially around weld seams and cut edges. And when welding and cutting operations are performed, unwanted impurities and edges result. Aquagain therefore recommends surface treatment only where it prolongs the service life of the item or can produce a more uniform finish.

When specifying the surface treatment and finish of plant and equipment, it is necessary to consider the consequences for:

- Hygiene

- Corrosion

- Visual and cosmetic appearance

- longevity and cost

When the task is the surface treatment of stainless steel, Aquagain is ready to provide extensive knowledge, solid experience and exceptional quality while ensuring an appropriate and optimised treatment in the situation concerned.

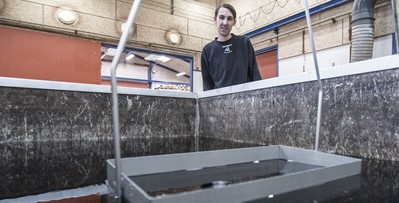

Aquagain reccomends immersion pickling as an effective chemical treatment in which the item is immersed in a vat containing a special pickling fluid. Correctly performed, immersion pickling gives the surface a uniform, open structure, free of deep, sharp-edged defects. The method also cleans the surface of a number of corrosion-sensitive inclusions. The advantages of immersion pickling are obvious: all item surfaces are pickled, including for example the insides of pipes and all corners and edges, and the treatment of individual items is 100% uniform. On the condition that parts and equipment are left indoors in a dry environment for 24 hours after finishing treatment, pickling results in the restoration of the protective surface film. Pickling produces an attractive, uniform and durable surface which minimises the risk of subsequent corrosion damage and prolongs service life.

Aquagain is capable of immersion pickling items of up to 7.0 x 1.5 x 0.8 m and 1000 kg. Larger items are spray pickled.

All Aquagain's surface treatment and finishing methods are environmentally approved and have the required certifications.

At Aquagain, you will meet skilled professionals with extensive know-how and solid experience in all types of surface treatment and finishing. You will meet people who are dedicated to their work and who understand your wishes and requirements. Our staff are familiar with the processes involved, understand your objectives and are capable of meeting your expectations for qualified sparring and the right surface in the situation concerned.

Want to know more about Surface treatment

- Call us and we will be happy to help